Individual layers of synthetic materials can collaborate for greater impact

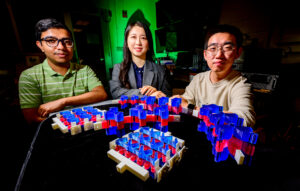

Professor Shelly Zhang, center, joined by fellow researchers Rahul Dev Kundu, left, and Shi Zhao, right, have developed a synthetic multi-layered material where each layer responds to stress differently. This original concept is derived from bones and clam shells, which use multiple layers to help heal from trauma. The researchers envision this being used in things like car bumpers and even wearable bandages.

Photo taken at the University of Illinois Urbana-Champaign on Wednesday, May 7, 2025.

(Photo by Fred Zwicky / University of Illinois Urbana-Champaign)

May 16, 2025 – After millions of years of evolution, some marine animals have developed complex protective shells composed of multiple layers that “work together” to withstand physical stress. It is precisely this cooperation between layers that makes the whole structure much stronger than any individual layer on its own.

Inspired by this principle, researchers at the University of Illinois have discovered a way to mimic the behaviour of such layered materials – like the nacre found in shells – using synthetic materials. This breakthrough has led to a new material design approach that could pave the way for advanced energy-absorbing systems in the future, such as car bumpers that adapt to the severity of a collision.

The study was published on May 16 in Science Advances under the title ‘Extreme nonlinearity by layered materials through inverse design.’