Razor-thin solution makes fuel cells cheaper and more environmentally friendly

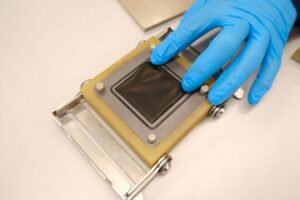

Thinner – but more efficient. Now the researchers will test how long the new membrane lasts (Photo: Silje Grytli Tveten)

May 29, 2025 – The Norwegian research institute Sintef in Trondheim has developed an ultra-thin membrane that significantly reduces material usage and costs in fuel cell production.

Fuel cells consist of a membrane and a catalyst, both of which are essential for converting hydrogen gas into electrical energy. The membranes are made from fluorinated materials that are harmful to the environment, while the catalyst consists of platinum. Together, the membrane and the catalyst account for up to 41 percent of the total cost of fuel cells. This is why the Norwegian researchers specifically focused on reducing these two components.

The researchers concluded that making the membrane even thinner did not negatively impact its performance, despite the reduction in material usage. Their calculations showed that the total cost of the membrane in hydrogen fuel cells could be reduced by as much as 20 percent, while the content of harmful PFAS could be lowered by 33 percent.

The study was published at the end of last year in the Journal of The Electrochemical Society under the title ‘The Influence of Membrane Thickness and Catalyst Loading on Performance of Proton Exchange Membrane Fuel Cells.’